|

|

|

|

|

|

|

|

|||||||||

Post Reply |

|

|

Thread Tools | Search this Thread |

| 12-30-2014, 07:57 PM | #24 |

|

Lieutenant

49

Rep 510

Posts |

Yeah, I would also like to know why the client asked for the engine to be inspected...was it just a precautionary measure?

|

|

Appreciate

0

|

| 12-30-2014, 08:10 PM | #25 | |||

|

BimmerPost Supporting Vendor

731

Rep 3,735

Posts  |

Quote:

In this particular engine, where the connecting rod bolts (ARP) were assembled and torqued exactly to ARP's specification using their assembly lubricant, a certified and calibrated torque wrench (non click type) shows us all something very important: this very engine, with factory connecting rod bearings and bolts exhibited very accelerated bearing wear on the top and bottom of the shells. Now in this particular situation as well, I am not saying/implying that the factory bolts are over torqued, they can very well be under torqued or they simply can't retain ideal torque and cause an issue. Per CLEVITE, an over-torqued bearing cap will result in excessive crush, which will create accelerated wear at the bearing parting line, not at the top and bottom of the shells. Also per CLEVITE, and under-torqued or fastener that is not holding correct torque would result in insufficient bearing crush and create uneven wear at the top and bottom of the bearing shells, which is what we see here. Not enough crush can also lead to a bearing not being tightly held within the rod housing and free to move around in the housing. This also hurts heat transfer in regards to the bearing surface. Overheating will kill a bearing. Quote:

Quote:

Per CLEVITE, and over-torqued connected rod bolt would yield in excessive crush creating accelerated wear at the parting lines of the bearings and under-torqued fasteners or fasteners that lose their torque due to excessive fastener stretch will yield wear at the bottom and top of the bearing shells which is evident here and almost all S65B40's with bearing wear. I purchased this engine from a client, he has a new engine in his vehicle now. He knows about this report, post and engine tear down.

__________________

BMW PERFORMANCE SPECIALISTS. Race Engines. Suspension. F/I. Brakes. Race Preparation. Factory Service. Alignments.

OFFICIAL PARTNERS: KW. MOTON. Brembo. AP Racing. BBS Motorsport. iND. HRE. Turner Motorsport. VAC. BMW Motorsport. Facebook | Instagram | Yelp! | Flikr Phone: 949-233-0448 | E-Mail: info@mrfengineering.com |

|||

|

Appreciate

1

NekMinnit9.00 |

| 12-30-2014, 08:13 PM | #26 | |

|

Private First Class

5

Rep 100

Posts |

The coating will not band-aid an oiling issue, I use Calico DFL coated bearings in many of our race motors, and if something goes wrong it wears away very quickly. There's some other answer here, whether it's a tolerance stack in the parts on this motor equaling more clearance, or the bolts being stretched differently which alters the housing bore, etc...

Quote:

All machined parts have manufacturing tolerances, it's very possible that this motor has tolerance stack to the low side on the crank, and the high side on the connecting rod big end to where the bearing clearances are in line with what we would want to see in a performance application. The only way to know is to measure, until there's real numbers it's all speculation. The info about the use of an ARP rod bolt is interesting, generally when switching to an ARP bolt it will be required that you resize the rod, that means you have to cut the cap and hone the big end bore in order to make it round and on size again because the (desired) higher clamp load of the higher grade hardware has distorted and changed the sizing on the big end bore. For an in-chassis retrofit you'll generally use a higher grade bolt, but with an undercut shank so that the clamp load at designed torque/stretch is effectively the same and the big end bore doesn't change, but you have a stronger material so it won't exhibit as much spring action after that. It could be that the spec that ARP is supplying ends up leaving the housing bore on the rod loose which translates into a looser bearing clearance...at the risk of less bearing crush. Speculation. |

|

|

Appreciate

0

|

| 12-30-2014, 08:34 PM | #27 | |

|

Major General

4995

Rep 6,862

Posts |

Quote:

I think what others have been getting at (and I am asking as well with this post) is why was a seemingly good engine torn apart? Dont take this as a knock on you or infer that anyone is doubting your credibility/intentions. It just seems odd to tear a working engine apart coupled with the comment that the original owner swapped this working engine for a new one. |

|

|

Appreciate

0

|

| 12-30-2014, 09:44 PM | #28 | |

|

BimmerPost Supporting Vendor

731

Rep 3,735

Posts  |

Quote:

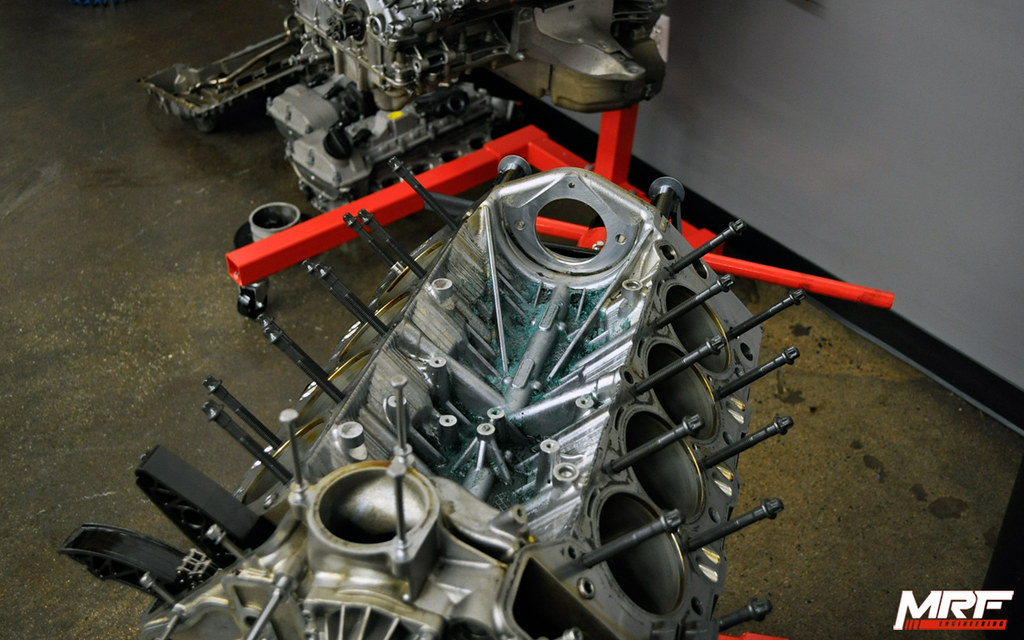

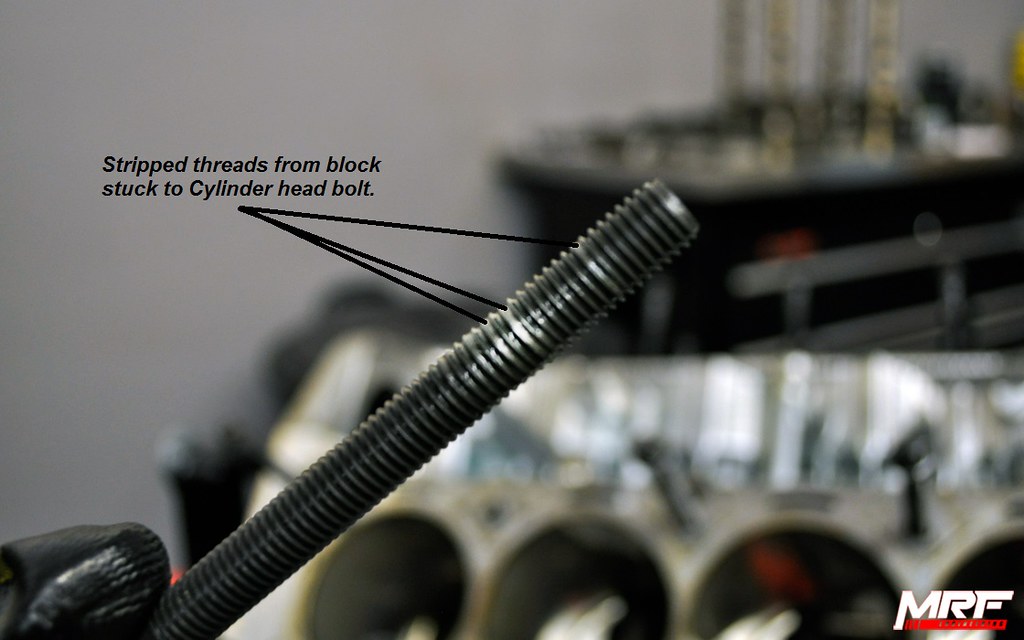

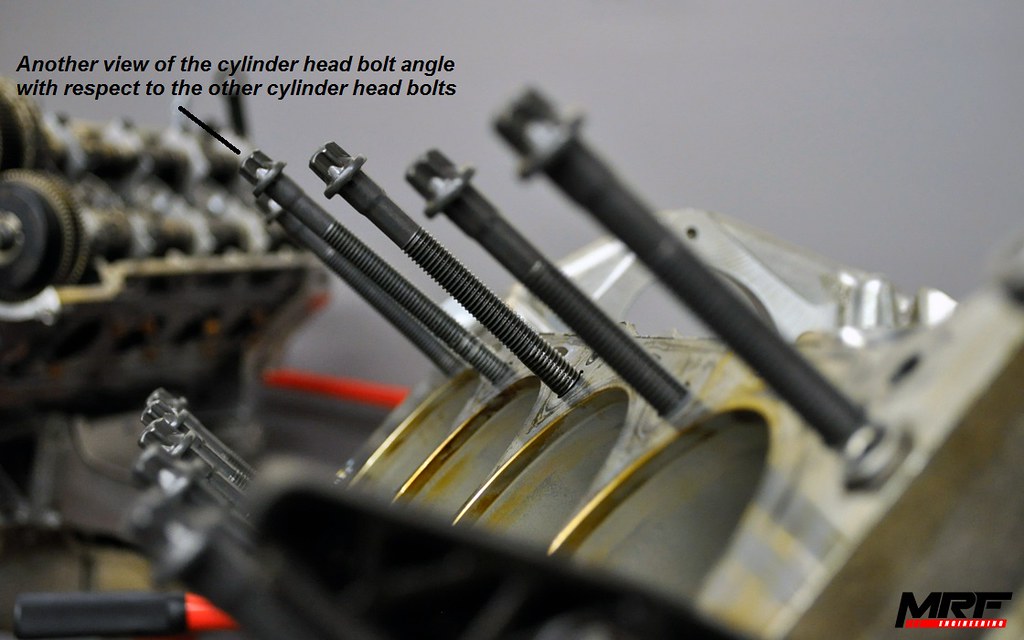

There is a crack in the block. To keep it very simple, as this also falls in line with assembly error, the crack on the block (the valley of the block), occurred on the outside part of the block where the cylinder head bolts would be. During tear down of this motor, I observed everything about this engine very particularly. The cylinder head bolt that resides where the crack occurred on this block was actually cross threaded into the blocks threading. As a result, the bolt was at a slight angle and the head fastener stressed the thin aluminum housing on that part of the block and cracked it, causing coolant to leak. Other than that, this was a fully running and healthy engine with no issues. You will also see in one of the images of the valley filled with coolant as a result of the block crack. Attached are some images depicting the said description.

__________________

BMW PERFORMANCE SPECIALISTS. Race Engines. Suspension. F/I. Brakes. Race Preparation. Factory Service. Alignments.

OFFICIAL PARTNERS: KW. MOTON. Brembo. AP Racing. BBS Motorsport. iND. HRE. Turner Motorsport. VAC. BMW Motorsport. Facebook | Instagram | Yelp! | Flikr Phone: 949-233-0448 | E-Mail: info@mrfengineering.com |

|

| 12-30-2014, 10:30 PM | #30 |

|

Captain

212

Rep 875

Posts |

Very interesting in deed. Is this the first engine to show no bearing wear? I just changed to WPC with ARP bolt at 86k miles. My bearings definitely showed sign of wears and a couple bearings were kinda loose on the cap. If ARP is the solution, then I won't have to worry about this again. Will definitely follow the development of this thread.

|

|

Appreciate

0

|

| 12-30-2014, 10:53 PM | #31 |

|

First Lieutenant

23

Rep 386

Posts |

Malek,

Do you have pics of the full set of OEM bearings that came from this motor? Was the one pictured the worst looking of all of them, best looking of all of them, or somewhere in between? Reason I ask is that if the other bearings looked ok then what some other folks have said about tolerance stack up being in favor of engine longevity could also be a big part of the excellent wear on the VAC bearings. If you have pics and wouldn't mind posting the full set that would be great. If not, do you remember which cylinder this bearing was from? I'm assuming it's the top shell? Thanks. |

|

Appreciate

0

|

| 12-30-2014, 10:53 PM | #32 |

|

Major General

1570

Rep 8,075

Posts

Drives: 11 E90 M3 Individual

Join Date: Mar 2006

Location: Houston, TX

|

I think this makes more sense. In my discussions about bearing clearances outside of this forum, tighter clearances for higher RPM engines aren't necessarily wrong. It does require more maintenance (faster wear) and more precise assembly.

The issue really comes down to precision. Like any machine shop, I'm sure the assembly line for S65 engines float within some tolerances. Under the right conditions, you get a situation where a couple of specs are far enough off yet within tolerance to cause an issue. At least that's my theory. But very interesting discussion.

__________________

2018 F30 320iX Melbourne Red

2011 E90 M3 Monte Carlo Blue 2004 E46 M3 Imola Red 2000 E36/7 Z3 Steel Blue |

|

Appreciate

0

|

| 12-30-2014, 11:12 PM | #33 |

|

Colonel

274

Rep 2,664

Posts

Drives: Goggomobil

Join Date: Jul 2007

Location: Kangaroo land

|

Further to my prior post, this does open a totally different can of worms ...

__________________

F86 X6///

|

|

Appreciate

0

|

| 12-31-2014, 01:07 AM | #34 |

|

Captain

270

Rep 888

Posts |

This thread is going to get interesting. The interesting take away is bearings with theoretically less clearance and oil that is known to be thicker shows up perfect bearing wear. Now hopefully we have some more conclusive data points like this to go off of.

I think one thing we can all VERY much appreciate is Malek taking the time to really inform the community of this data that can help things tremendously. If it were the case of improperly torqued rod bearings I think ARP will be out of stock by tomorrow. Very good information! |

|

Appreciate

0

|

| 12-31-2014, 01:23 AM | #35 | |

|

Lieutenant Colonel

140

Rep 1,665

Posts |

Quote:

|

|

|

Appreciate

0

|

| 12-31-2014, 01:47 AM | #37 |

|

Lieutenant Colonel

140

Rep 1,665

Posts |

Malek can you post journal sizes of the crank and bore size of the rods with bearings installed and torqued with both ARP and factory rod bolts please?

And then if you still have them, do the same thing for the original factory bearings that showed excessive wear. Last edited by OM VT3; 12-31-2014 at 02:18 AM.. |

|

Appreciate

0

|

| 12-31-2014, 02:13 AM | #38 |

|

Major

237

Rep 1,095

Posts

Drives: 09 SC E90 M3 / 13 F10 M5

Join Date: Sep 2011

Location: Dallas, TX

|

thanks for posting this!

__________________

|

|

Appreciate

0

|

| 12-31-2014, 04:45 AM | #39 |

|

Major

1056

Rep 1,459

Posts |

|

|

Appreciate

0

|

| 12-31-2014, 05:28 AM | #40 | |

|

Brigadier General

2511

Rep 4,381

Posts |

Quote:

Great work by MRP. |

|

|

Appreciate

0

|

| 12-31-2014, 06:32 AM | #41 |

|

Colonel

97

Rep 2,002

Posts |

If the ARP non stretch rod bolts, tq'd correctly, are the fix, and the OEM bolts are tq'd to tightly, it would explain why some engines go 100k-150k miles with no issues and others have issues at 8k miles or 30k miles.

If in fact the clearances are to tight i've always thought there was no way a engine would make 100k-150k miles. Something else must be going on.... maybe this is it?

__________________

ESS 650 ACM-R Upgrades |

|

Appreciate

0

|

| 12-31-2014, 06:43 AM | #42 |

|

Colonel

274

Rep 2,664

Posts

Drives: Goggomobil

Join Date: Jul 2007

Location: Kangaroo land

|

The problem is mass production and BMW tooling. Probably the result of /// becoming a series production to satisfy the bean counters.

__________________

F86 X6///

|

|

Appreciate

0

|

| 12-31-2014, 06:44 AM | #43 |

|

Lieutenant General

5231

Rep 10,614

Posts |

If that BMW engine builder incorrectly torqued the road bolts and cross threaded a head stud, he should be fired. Maybe he is a drunk and assembled 1% of the S65 motors and these are the ones having problems.

There seem to be many properly assembled S65 with stock bearings and stock rod bolts that have no issues. I am curious about the BMW instructions for assembling with new rod bolts. The ones I used when doing a preventative maintenance bearing change specified torquing through the 3 stage sequence 3 times for new bolts. I thought I had seen BMW instructions for older BMW motors that did not require doing the 3 stage sequence 3 times. Maybe if you do it only once, there is some added stretch and this is what causes the problems. Also, if ARP bolts are the answer because they get the torque perfect, do both the original and new ARPs work, because they have different torque: ARP2000 bolts should be 45 ft-lb, Custom Age 625+ is 60 ft-lb. Last edited by pbonsalb; 12-31-2014 at 06:54 AM.. |

|

Appreciate

1

undecided82.50 |

| 12-31-2014, 07:03 AM | #44 |

|

Major General

423

Rep 5,328

Posts |

so are we saying bmw made this same hardware error/calibration error with nearly 2 decades of ///M engine, as from what i know the s54, and s85 have the same issue.

surely this is way to early to jump on the bandwagon, this is one example , however interesting it may be its far from conclusive. On a side note, its GREAT to see this one example showing so well after 40k of supercharged miles, great post OP.

__________________

Z4MR VT2 - Clubsport build.

Multi award winning Detailing | Wrap | PPF specialists UK based - www.topwrapz.com |

|

Appreciate

0

|

Post Reply |

| Bookmarks |

|

|