Article: Geometrical parameters of engine bearings

Article: Hydrodynamic Bearings

Article: Fundamentals of Fluid Film Journal Bearing Operation and Modeling

I've got to be honest, I didn't know anything about bearing eccentricity when I created this thread, and I doubt I'll be able to add any insight into the subject. As I learned, the bearing is not round, it is slightly oval shaped. The bearing clearance is the smallest at 90 degrees to the parting line, and largest at the parting line. This ratio between the two is called "eccentricity" and as I understand it is designed to allow oil to escape and be replenished. If there is too little eccentricity, it would be harder for oil to esscape. If the oil doesn't escape then the trapped oil can become super heated and cause both bearing and connecting rod damage. This could be one explanation why connecting rods such as the ones below shows signs of super heating that lead to catastrophic failures.

According to the first article above, these are values one could expect to measure for bearing eccentricity:

For passenger cars: 0.0002 - 0.0008” For high performance cars: 0.0006 - 0.0012”

The values above represent a fixed value, not a ratio of rod journal diameter or surface area. So to me, that spec above doesn't make sense. I would expect it to be more of a ratio of journal surface area instead of a fixed value. Regardless, the information above is valuable for our understanding.

Where to measure

According to the article above, I should measure eccentricity at 3/8 inch above the parting line for journals between 1.6 - 3.4 inch diameter. At first, this is not what I did. I had completed the measurements and I had already written 90% of this article and prepared 100% of the charts and graphs. But the perfectionist in me wouldn't let it go. The 702/703's were still installed in the rods, so I quickly took the measurements. The following night, I replaced the 702/703's with the 088/089's and took those measurements too.

Marking and Measuring

For this article, I had measured at 5, 45, 90, 135, and 175 degrees on 088/089 and 702/703 bearings. To capture the "official" eccentricity measurements according to the abovementioned article, I also measured at 20 and 160 degrees as well. Before taking any measurements, I did some quick calculations and marked the connecting rod locations as shown below.

088/089 Bearing Eccentricity (while measuring)

088/089 Bearing Eccentricity (while measuring)

702/703 Bearing Eccentricity (while practicing)

702/703 Bearing Eccentricity (while practicing)

Data Results

088/089 Bearing Results

Bearing Bore Measurements by Angle

Data Results

088/089 Bearing Results

Bearing Bore Measurements by Angle

| 088/089 Ecc. Meas. | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | MIN | Max | Official | Min Dev. | Max Dev. |

| 005 Degrees | 2.05070 | 2.05040 | 2.05035 | 2.05055 | 2.05060 | 2.05050 | 2.05035 | 2.05050 | 2.05035 | 2.05070 | 2.05049 | -0.00014 | 0.00021 |

| 020 Degrees | 2.04860 | 2.04860 | 2.04880 | 2.04880 | 2.04880 | 2.04885 | 2.04885 | 2.04885 | 2.04860 | 2.04885 | 2.04877 | -0.00017 | 0.00008 |

| 045 Degrees | 2.04815 | 2.04800 | 2.04840 | 2.04815 | 2.04830 | 2.04805 | 2.04835 | 2.04830 | 2.04800 | 2.04840 | 2.04821 | -0.00021 | 0.00019 |

| 090 Degrees | 2.04785 | 2.04790 | 2.04795 | 2.04795 | 2.04800 | 2.04795 | 2.04800 | 2.04800 | 2.04785 | 2.04800 | 2.04795 | -0.00010 | 0.00005 |

| 135 Degrees | 2.04800 | 2.04820 | 2.04820 | 2.04840 | 2.04820 | 2.04810 | 2.04840 | 2.04820 | 2.04800 | 2.04840 | 2.04821 | -0.00021 | 0.00019 |

| 160 Degrees | 2.04860 | 2.04860 | 2.04880 | 2.04870 | 2.04885 | 2.04880 | 2.04870 | 2.04885 | 2.04860 | 2.04885 | 2.04874 | -0.00014 | 0.00011 |

| 175 Degrees | 2.05060 | 2.05100 | 2.05035 | 2.05060 | 2.05055 | 2.05015 | 2.05050 | 2.05055 | 2.05015 | 2.05100 | 2.05054 | -0.00039 | 0.00046 |

Bearing Clearance Measurements by Angle

| 088/089 Ecc. Clr. | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | MIN | Max | Official | Min Dev. | Max Dev. |

| 005 Degrees | 0.00285 | 0.00250 | 0.00240 | 0.00260 | 0.00260 | 0.00255 | 0.00235 | 0.00250 | 0.00235 | 0.00285 | 0.00254 | -0.00019 | 0.00031 |

| 020 Degrees | 0.00075 | 0.00070 | 0.00085 | 0.00085 | 0.00080 | 0.00090 | 0.00085 | 0.00085 | 0.00070 | 0.00090 | 0.00085 | -0.00015 | 0.00005 |

| 045 Degrees | 0.00030 | 0.00010 | 0.00045 | 0.00020 | 0.00030 | 0.00010 | 0.00035 | 0.00030 | 0.00010 | 0.00045 | 0.00026 | -0.00016 | 0.00019 |

| 090 Degrees | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 |

| 135 Degrees | 0.00015 | 0.00030 | 0.00025 | 0.00045 | 0.00020 | 0.00015 | 0.00040 | 0.00020 | 0.00015 | 0.00045 | 0.00026 | -0.00011 | 0.00019 |

| 160 Degrees | 0.00075 | 0.00070 | 0.00085 | 0.00075 | 0.00085 | 0.00085 | 0.00070 | 0.00085 | 0.00070 | 0.00085 | 0.00079 | -0.00009 | 0.00006 |

| 175 Degrees | 0.00275 | 0.00310 | 0.00240 | 0.00265 | 0.00255 | 0.00220 | 0.00250 | 0.00255 | 0.00220 | 0.00310 | 0.00259 | -0.00039 | 0.00051 |

Complete 088/089 Bearing Specifications with Eccentricity

| Engine | S65B40 | |

| Bearing Dimensions (088/089 Bearings) | Metric Dimensions | SAE (Inch) Dimensions |

| Rod + Bearing Dimensions | 52.0180 mm | 2.04795 inch |

| Rod + Bearing Variance (1) | 52.0141 - 52.0281 mm | 2.04780 - 2.04835 inch |

| Nominal Rod Bearing Clearance | 0.0357 mm | 0.00140 inch |

| Bearing Clearance Variance (1) | 0.0305 - 0.0470 mm | 0.00120 - 00185 inch |

| Bearing Clearance Tolerance | -0.0051 - +0.0114 mm | -0.00020, +0.00045 inch |

| Bearing Clearance per Journal inch | | 0.00068 inch/inch |

| Bearing Clearance per Journal Inch Variance (1) | | 0.00059 - 0.00090 inch/inch |

| Bearing Eccentricity | 0.0203 mm | 0.00080 inch |

| Bearing Eccentricity Variance | 0.0178 - 0.0216 mm | 0.00070 - 0.00085 inch |

| Bearing Eccentricity Tolerance | -0.0038, +0.0013 mm | -0.00015, +0.00005 inch |

702/703Bearing Results

Bearing Bore Measurements by Angle

| 702/703 Ecc. Meas. | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | MIN | Max | Official | Min Dev. | Max Dev. |

| 005 Degrees | 2.05280 | 2.05290 | 2.05290 | 2.05280 | 2.05250 | 2.05260 | 2.05270 | 2.05290 | 2.05250 | 2.05290 | 2.05276 | -0.00026 | 0.00014 |

| 020 Degrees | 2.05045 | 2.05035 | 2.05035 | 2.05020 | 2.05010 | 2.05020 | 2.05035 | 2.05035 | 2.05010 | 2.05045 | 2.05029 | -0.00019 | 0.00016 |

| 045 Degrees | 2.04900 | 2.04880 | 2.04880 | 2.04920 | 2.04870 | 2.04890 | 2.04880 | 2.04890 | 2.04870 | 2.04920 | 2.04889 | -0.00019 | 0.00031 |

| 090 Degrees | 2.04830 | 2.04815 | 2.04840 | 2.04820 | 2.04835 | 2.04830 | 2.04820 | 2.04820 | 2.04815 | 2.04840 | 2.04820 | -0.00005 | 0.00020 |

| 135 Degrees | 2.04900 | 2.04890 | 2.04900 | 2.04885 | 2.04900 | 2.04890 | 2.04890 | 2.04885 | 2.04885 | 2.04900 | 2.04893 | -0.00007 | 0.00008 |

| 160 Degrees | 2.05035 | 2.05045 | 2.05035 | 2.05020 | 2.05040 | 2.05040 | 2.05035 | 2.05020 | 2.05020 | 2.05045 | 2.05034 | -0.00014 | 0.00011 |

| 175 Degrees | 2.05280 | 2.05300 | 2.05270 | 2.05280 | 2.05285 | 2.05290 | 2.05285 | 2.05300 | 2.05270 | 2.05300 | 2.05286 | -0.00016 | 0.00014 |

Bearing Bore Measurements by Angle

| 702/703 Ecc. Clr. | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | MIN | Max | Official | Min Dev. | Max Dev. |

| 005 Degrees | 0.00450 | 0.00475 | 0.00450 | 0.00460 | 0.00415 | 0.00430 | 0.00450 | 0.00470 | 0.00415 | 0.00475 | 0.00450 | -0.00035 | 0.00025 |

| 020 Degrees | 0.00215 | 0.00220 | 0.00195 | 0.00200 | 0.00175 | 0.00190 | 0.00215 | 0.00215 | 0.00175 | 0.00220 | 0.00215 | -0.00040 | 0.00005 |

| 045 Degrees | 0.00070 | 0.00065 | 0.00040 | 0.00100 | 0.00035 | 0.00060 | 0.00060 | 0.00070 | 0.00035 | 0.00100 | 0.00063 | -0.00027 | 0.00037 |

| 090 Degrees | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 |

| 135 Degrees | 0.00070 | 0.00075 | 0.00060 | 0.00065 | 0.00065 | 0.00060 | 0.00070 | 0.00065 | 0.00060 | 0.00075 | 0.00066 | -0.00006 | 0.00009 |

| 160 Degrees | 0.00205 | 0.00230 | 0.00195 | 0.00200 | 0.00205 | 0.00210 | 0.00215 | 0.00200 | 0.00195 | 0.00230 | 0.00200 | -0.00005 | 0.00030 |

| 175 Degrees | 0.00450 | 0.00485 | 0.00430 | 0.00460 | 0.00450 | 0.00460 | 0.00465 | 0.00480 | 0.00430 | 0.00485 | 0.00460 | -0.00030 | 0.00025 |

Complete 702/703 Bearing Specifications with Eccentricity

| Engine | S65B40 | |

| Bearing Dimensions (702/703 Bearings) | Metric Dimensions | SAE (Inch) Dimensions |

| Rod + Bearing Dimensions | 52.0243 mm | 2.04820 inch |

| Rod + Bearing Variance | 52.0230 - 52.0294mm | 2.04815 - 2.04840 inch |

| Nominal Rod Bearing Clearance | 0.0419 mm | 0.00165 inch |

| Bearing Clearance Variance | 0.0394 - 0.0483 mm | 0.00155 - 0.00190 inch |

| Bearing Clearance Tolerance | -0.0025 - +0.0064 mm | -.00010 - 0.00025 inch |

| Bearing Clearance per Journal inch | | 0.00081 inch/inch |

| Bearing Clearance per Journal Inch Variance | | 0.00076 - 0.00093 inch/inch |

| Bearing Eccentricity | 0.0508 mm | 0.00200 inch |

| Bearing Eccentricity Variance | 0.0445 - 0.0584 mm | 0.00175 - 0.00230 inch |

| Bearing Eccentricity Tolerance | -0.0064, +0.0076 mm | -0.00025, +0.00030 inch |

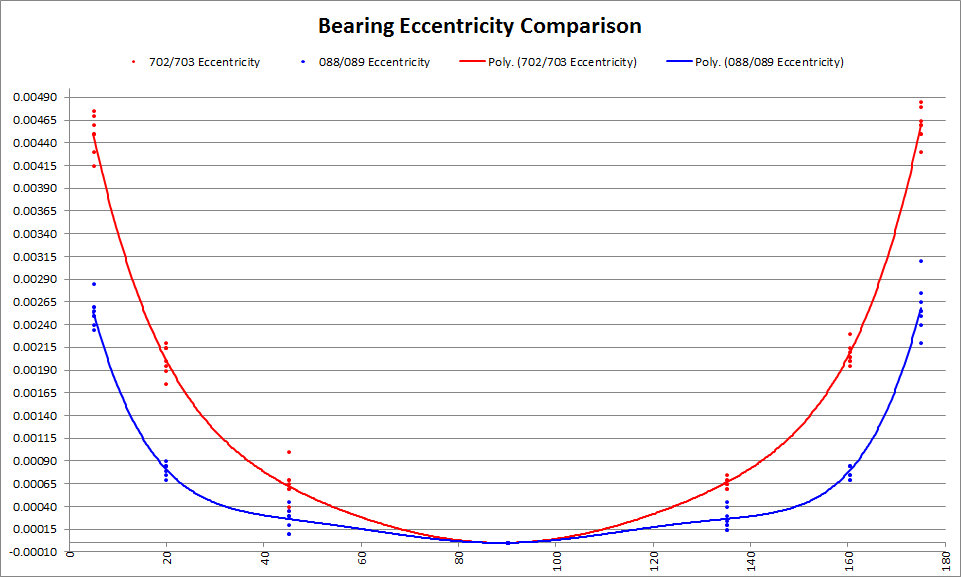

Even in this manner, it's hard to get a feel for the data. So graphing is the only way to look at it to see what's really going on. Even though the charts and specifications all say there's a difference, just what does it look like on a graph?

Graphs and Conclusions

I created the graphcs as a scatter plot with a "best fit" polynomial line to follow the contour of the measurements. That's when the results really jumped out and you could visually see for the first time how these bearings have changed. Not only did the bearing clearance change between 088/089 and 702/703, but so did the eccentricity. The eccentricity didn't change by a little, it seems to have changed by a LOT! See for yourself.

"Common" Eccentricity

Conclusions and my $0.02

Conclusions and my $0.02

When I was asked to measure bearing eccentricity, I had no idea what I would find. I guess I presumed that 088/089 bearings would both follow the same guidelines and show the same eccentricity. Even when I was measuring and looking at the numbers, I was making that presumption and didn't notice any differences. It wasn't until I looked at the graph that it became very obvious that something radical had changed.

The bearing eccentricity changed from 0.00085 inch on the 088/089 bearings to 0.00200 inch on the 702/703 bearings. That's a 2.5 times increase in eccentricity clearance which will allow the oil to escape the rods that much better.

It wasn't too long ago that I thought there was only one bearing part number. But that proved wrong! Between the S85 and S65 lifespan there were a total of FOUR different bearing designs, but I believe only two of those ever saw production on the S65. The older designs are long gone and we'll never get a fresh set of those bearings to test and see how they differ from these (I already tried).

After I discovered the new bearing designs (702/703's), I thought they shared the same dimensions as the originals (088/089's). But that proved wrong too. These new measurements proved that the 702/703 bearings changed material, clearance, and pretty radically changed eccentricity.

By now I think I have a much clearer picture than when I started. Some will say (and have already said) that the 702/703 bearings changed dimensions because of the materials change. I've got to be honest, that sounds very compelling on the surface but there's one thing about it that really bugs me. Nobody has explained why the harder material would require extra clearance when 1) the bearing is never supposed to touch the journal, and 2) it would seem that it has less friction than the older lead/copper design. So to me, the dimensional changes of the new bearing weren't based on a simple materials change, but were much more deliberate.

The S65 started production with 088/089 bearings. But something was wrong: relatively new engines were puking connecting rods. The clearances were too tight, the side clearance was too tight, the eccentricity was too tight, and the oil was too thick. As a result, it seems like tolerance stack up with a bad luck of the draw, and your engine might end up looking like the photos shown above. So BMW decided to do something about it.

When BMW designed the newer 702/703 bearings to comply with lead-free regulations, they made changes. I believe they took steps to mitigate these problems. BMW increased the rod bearing clearance, and they increased the eccentricity by 250%. Those changes mean two of the four possible "trouble spots" I mentioned above have now been addressed.

In August 2013, BMW-NA made a specification change to the oil allowed in the S85/S65. After five years of only allowing 10W60, BMW relaxed the specifications and is now allowing LL-01 approved 0W40, 5W30, and 5W40 weight oils. Three of the four potential trouble areas we identified in the S65 have now been addressed. The only thing that remains is the rod side clearance. With the help of some buddies down the road, I might be able to take measurements on a wide range of BMW S65 crankshafts to see if the rod side clearance has changed throughout the three different crankshafts manufactured for the S65. If that comes to pass, I'll be sure to post the results either way (changed side clearance or not).

Van Dyne identified two of the four potential problems (journal clearance, rod side clearance), Kawasaki00 and BMWLVR were advocates for thinner oils, and we really kind of backed in to the eccentricity discussion and discovered a big change eccentricity clearances.

Some will say it's all a coincidence. They are just as entitled to their opinion as I am mine. I don't think it's a coincidence. For whatever reason, BMW changed (coincidence or not), BMW had three years with old bearing; then three years with new bearings; then changed to allow thinner oils. Sure it may all be a coincidence, but to me, it seems like they were chasing something and were making incremental changes to mitigate what they saw as a problem.

Blast away.