Hey guys, not exactly automotive but interesting none the less.

I work for the only non-manufacturer ran General Electric locomotive overhaul facility in North America and I figured I'd share a few pics of some of the cool stuff I get to work on.

I mainly work on GE 7FDL16 series engines. They are 10,700CID V16s rated at 4,400hp/20,000ftlbs@1055RPM. Each locomotive is rated at ~140,000 pounds of tractive effort(pulling force.) Total locomotive weight is 400,000lbs.

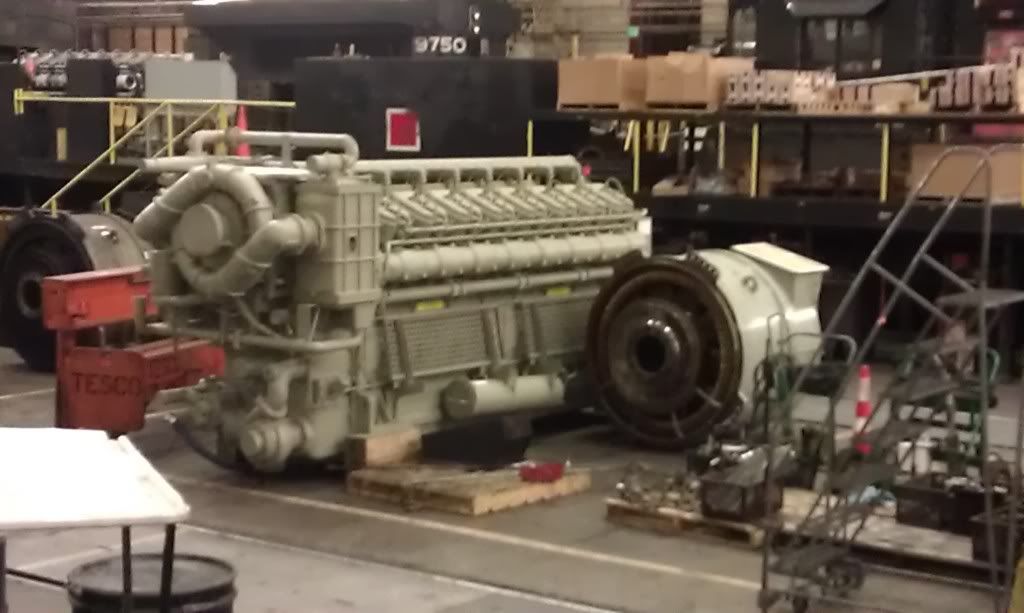

This is a complete engine setting next to the alternator that will bolted to rear of the engine and provides the power necessary to turn the traction motors. Combined weight is ~65,000lbs.

This is just the bare block. The holes in the top are where each Power Assembly sit. The square holes in the side provide access for inspection/ repair.

This is the crankshaft. It is ~11 feet long and weighs 4,200lbs.

The pistons are a 2 piece design where the crown and skirt are bolted together. Combined weight of crown and skirt is ~50lbs. This particular piston had a failure of the wrist pin causing damage to both the skirt and cylinder walls.

The turbochargers weigh 1,900lbs and are designed to provide 36psi of pressure in two separate 11ID intake manifolds.

Here are a couple pics of the turbo mounted. One from the front, one from the rear and one of just the exhaust manifold.

The pics from the rear is obstructed on the left by a power assembly and on the right by a water to air intercooler.

Exhaust manifold

I love working on this stuff and if you guys have any questions I'll be happy to answer them to the best of my abilities.