HRE wheels has been a stronghold of the US wheel manufacturing business for nearly three decades and over this time has become an example of just what’s possible with hard work, perseverance, and dedication to building the best parts possible. This summer while visiting some clients a few IND staff members were fortunate enough to stop by HRE’s manufacturing facility for a tour of the inner workings of the company.

Please join us for this photo preview of HRE!

First impressions are always critical, and HRE’s building does not disappoint. The manicured face, host of modified cars parked outside, and the logo styled to resemble an HRE center cap all give even the outside of the building a unique personality.

The HRE office immediately makes a statement about the company’s core values. The office looks colorful and playful, with images of some of the world’s best sports cars decorating the walls.

One of my favorite things about HRE as a company is their embrace of color. Most forged wheel manufacturers in the US will rarely stray from the monochrome, but HRE’s focus for years has been on expanding their color palette.

The offices are full of displays of HRE wheels. Everything from classic wheel styles to brand new wheels still in development were inside the common office room.

One of my favorite displays at the office was this, the build process of an HRE wheel from start to finish. Here the wheel starts as a blank aluminum core, is forged into it’s basic shape, and finally machined into the finished P40SC wheel.

Walking from the organized offices into the bustle of the manufacturing facility was a large contrast. Every square foot of shop space seemed in use, and I’m fairly certain that I have never seen more wheels and wheel pieces in one place in my life.

Computer Numerical Control (CNC) machinery occupied the majority of the building to our right, and to our left were stacks of mushroom shaped forged blanks, destined to be cut into wheel centers for three piece wheels.

HRE’s production facility is directly behind their main offices, in the same building. This allows for any production issues or engineering revisions to be implemented immediately- something that translates directly into better service and response times.

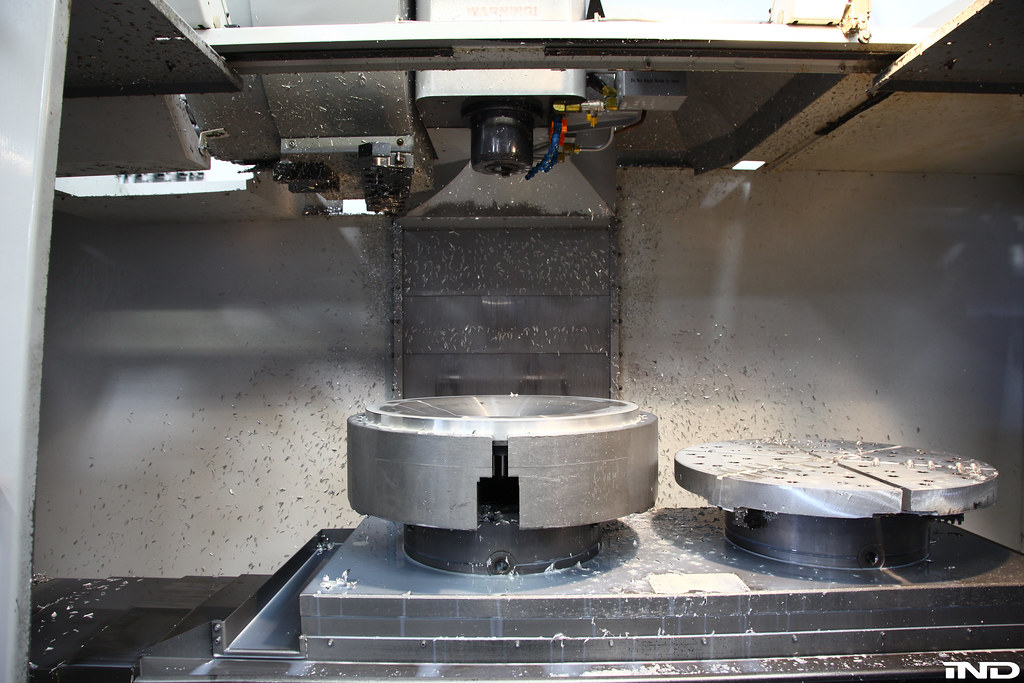

HRE’s host of CNC mills are in a constant state of flux, with newer and updated machines added frequently to keep up with changing and progressively more complex wheel designs. The constant hum of the CNC machines instilled an aura of progress and productivity to the room.

Taking a peak inside one of the CNC machines, we could literally watch a new three piece wheel center taking shape.

Finished wheel centers are attached to their order numbers and move down the assembly line for finishing and final assembly.

Each wheel is then taken to a special chemical bath to remove any impurities or contaminants prior to final finishing.

I was amazed to discover that the ever popular brushed aluminum finish found on HRE wheels is applied entirely by hand! Only a handful of HRE’s best technicians are able to meticulously brush the face of each wheel to create the well known pattern.

Final assembly and quality check of each wheel is done by hand. Every wheel is inspected for machining or finish flaws before being shipped, and three piece wheel assembly is performed using either high strength stainless steel fastners or ultra light weight titanium hardware.

Finally, wheels are packed, boxed, and ready to ship to their respective owners. Walking past the shipping area gave us a great view of some of HRE’s new finishes, including matte and gloss bronzes, a great gloss black, and even a super bright blue!

Visiting the HRE facility left an impression of a true commitment to quality, an impressive sense of professionalism from each member of the HRE staff, and most of all a love for creativity, fun, and pushing the envelope. Thanks to all of the HRE staff for showing us around, and thanks to our readers for viewing this tour!