Quote:

Originally Posted by askiles

Can you tell us, what was the problem with the Cyba tips?

-Andy

|

There was a design problem with the tips, and it is very hard to explain, but I'll try with the help of a couple pics

The inner wall of the double-walled BMW tip ends at about this red line on the drawing and butt-meets with the pipe that actually carries exhaust gases from the muffler:

If you look at this picture, from left to right is the muffler to the end of the tip. This is a cross-section drawing. As you can see, the outer layer of the tip is riveted to the part that is welded to the muffler (BTW, the exiting 2.5" pipe actually carrying the exhaust gases lies inside this outer welded pipe).

CYBA's tip required that we drill out the rivet, remove the BMW tip and weld back on his tip (to "Welded to muffler" in the pic). However, if we did this, there would be a 1/4" gap all around the exiting pipe before hitting the CYBA tip. The reason is that CYBA's tip did not have an inner wall, just an outer shell. This isnt so much of a problem but if you follow that gap backwards to the muffler, you realize that the "Welded to muffler" as pictured is not totally welded, its spot welded top and bottom, and as a result there are lots of gaps.

Our concern was twofold - one that gases may follow backwards past that 1/4 gap (at idle for example). And secondly, that as flow increased, it would draw air from around the spot welds and create a undesirable sound (like a whistle). The only way to fix this was with either a lot of gap filling, or fabricating an inner wall, and at this point, we just didnt want to invest that much more time.

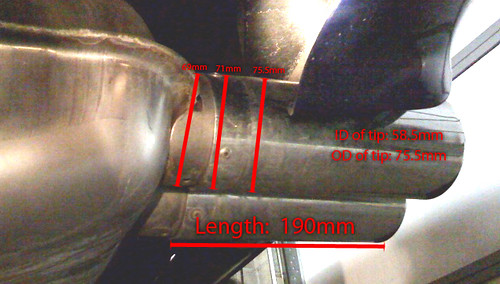

{edit: here is a shot of the inside of the pipe}

I have suggested to CYBA that he make slip on type tips that would go over the OEM tips, and secure with maybe spot weld, clamp or screw. This would solve a lot of problems, not require the purchaser to drop the exhaust to install, and would not vary a lot from his current design. Although not totally functional and perhaps mildly lame on the surface, the fact that its not real would be hard to spot from a distance. After having taken off the exhaust and gone through the welding, I just cant imagine that amount of effort just to change the tip color. It is a big time and effort investment IMO, especially if you don't have a good friend like Sam!