|

|

|

|

|

|

|

|

|||||||||

Post Reply |

|

|

Thread Tools | Search this Thread |

| 03-21-2015, 05:26 PM | #353 | |

|

BimmerPost Supporting Vendor

731

Rep 3,735

Posts  |

Quote:

It is semi-cheating in the regard you explained, because doing a rod bearing replacement doesnt constitute pulling the engine and tearing it down and starting from scratch. It doesn't allow us to spec the engine and basically "blueprint" to exacting specifications and move toward reducing and if possible eliminating tolerances. No matter what we do, whether bolts are the solution, or new bearings are the solution, it doesn't solve the issue of rod side clearance and the main bearing clearance. I can definitely throw in some new bolts into a few of the same rods, and when I get the bolts back from regular_guy (he was interested in borrowing them for some of his own measurements), I will load them back up without bearings and measure the housing bore and provide the values. In the meantime, I can perform this with unused OE BMW TTY bolts and get the data. Are you curious if the bearings are distorting the rod bore with the ARP's in comparison to the OE bolts?

__________________

BMW PERFORMANCE SPECIALISTS. Race Engines. Suspension. F/I. Brakes. Race Preparation. Factory Service. Alignments.

OFFICIAL PARTNERS: KW. MOTON. Brembo. AP Racing. BBS Motorsport. iND. HRE. Turner Motorsport. VAC. BMW Motorsport. Facebook | Instagram | Yelp! | Flikr Phone: 949-233-0448 | E-Mail: info@mrfengineering.com |

|

|

Appreciate

0

|

| 03-22-2015, 11:48 AM | #354 | |

|

Lieutenant Colonel

233

Rep 1,673

Posts |

Quote:

I also agree about that side clearance, that doesnt seem to be a problem with every engine, have looked at a few that it is a problem and a few not. None the less it still is another issue that unfortunately cant be fixed with the engine in the car.

__________________

Electronics Junkie, Engine Builder. Electronics Junkie, Engine Builder. |

|

|

Appreciate

0

|

| 03-22-2015, 06:02 PM | #355 |

|

Retired Curmudgeon

2985

Rep 4,047

Posts |

Great thread that I just read from TDC to BDC?! Great work in here, Malek. Thanks to you and other who have helped (and RG for the bearing thread).

Perhaps my reading comprehension is off (I have heard this once or twice), but with these failed engines was there any engine oil analysis done at any time? I'm looking for precursors to the impending doom of bearing failure. Thanks!

__________________

'19 X3 M40 Carbon Black/Oyster, '23 Jeep Grand Cherokee L Summit, Past BMWs: '18 M550i, '18 330 GT, '16 X5 40e, '11 E90M3, '06 X5 4.4, '03 330i ZHP, '02 M3, '97 Z3 2.8, '95 M3 (2x), '94 530i (manual), '92 525i (manual), '88 M3, '87 325iS |

|

Appreciate

0

|

| 03-22-2015, 07:07 PM | #356 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Lieutenant Colonel

427

Rep 1,947

Posts |

Part-1: Rod bolt clamping pressure:

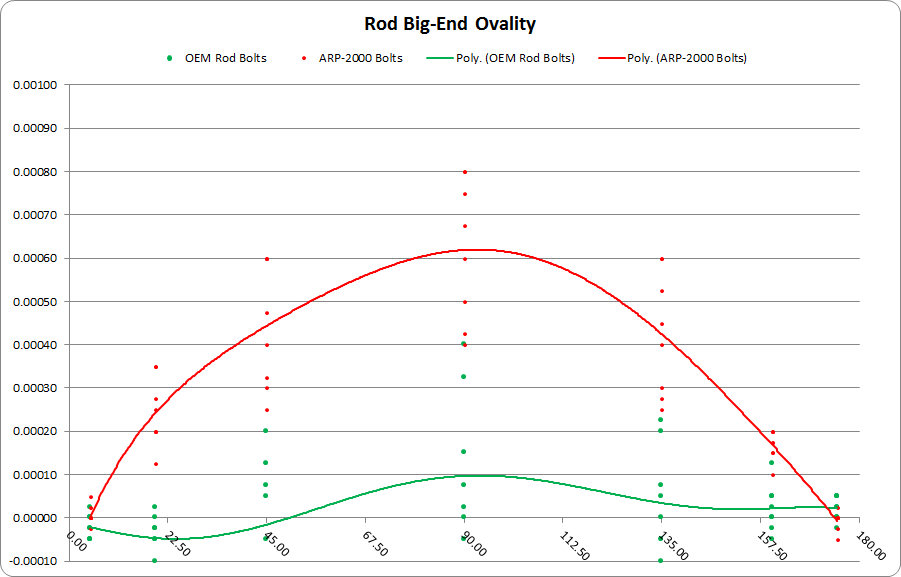

M3post reader, kawasaki00 measured the OEM rod bolt clamping pressure, along with the clamping pressure of two different types of Carrillo rod bolts. As he discovered, the OEM rod bolts offer far more clamping pressure vs. Carrillo rod bolts, and it's believed the clamping pressure (or lack thereof) may cause the rod big end bore distortion and lead to increased bearing clearance at 90-degrees. Increased bearing clearance is a good thing, but bore distortion is not. I'm pretty sure that increased clearance at the cost of bore distortion is not advised. However, I'll let kawasaki00 and the other engine experts comment on that. Here's the rod bolt clamping force data generated by kawasaki00:

Notes: Carrillo WMC bolts @ 50 degrees, 0.006 inch stretch Carrillo SPS bolts @ 54 degrees, 0.0065 inch stretch Part-2: Rod big-end ovality with different rod bolts: With the rod bolt clamping data above, the next test will see which rod bolt creates the roundest circle. This will test for the "ovality" of the rod big end bore by checking the measurements at seven different points around the circle. Although the ARP-2000 and ARP-625 rod bolts were not tested above, I believe the two Carrillo rod bolts are of similar quality and specifications. (kawasaki00 can comment on that.) For the most part, the OEM rod bolts create a near perfectly-round circle. Four of the eight rods I tested were 1/10000th of an inch or less out of round. That's probably what you would expect since these rods were honed (the process of making the circle round) with OEM rod bolts. The ARP-2000 rod bolts did not create a perfectly round circle. The ARP-2000 rod bolts, with less clamping pressure produced bore distortion at 90-degrees. The bore distorts larger towards 90-degrees, and this would explain Malek's and Van Dyne's measurement of increased clearance when using the aftermarket ARP bolts. But is this enough to matter? Kawasaki00 told me privately, yes, this is a significant amount of ovality, and he would not use these bolts unless he was also able to rehone the connecting rod big ends to make them round again. The data: OEM Rod Bolt Measurements: Torque Specifications: 20 Nm + 130 degrees

Ovality:

ARP-2000 Rod Bolt Measurements: Torque Specifications: 45 Ft-Lbs

Ovality:

Graph(s):  Next Steps: Next week, ARP-625 bolts will arrive. I will repeat this measuring process with the ARP-625 bolts and post the results when they are available. Thanks to Malek for loaning me the ARP-2000 rod bolts. Before returning them, I plan to measure bearing clearance. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Appreciate

0

|

| 03-30-2015, 12:10 AM | #357 |

|

Lieutenant

228

Rep 538

Posts |

I have only been half following these bearing discussions. But I find it interesting that there is a general disregard for the main bearings in these discussions. Especially given the fact that the OP here actually has had one of the motors with mains that likely failed prior to the rods.

It makes a world of difference in terms of the ultimate "fix" needed. As you can't really replace mains with the engine in the car. Is there any data out there now on the number of S65s with failing main bearings relative to failing rod bearings? BTW: Thanks for all the good work from everyone. I know these threads seem to get heated sometimes, but in the grand scheme of things it seems progress is being made! |

|

Appreciate

1

|

| 03-30-2015, 08:59 AM | #358 |

|

Captain

252

Rep 633

Posts |

Folks,

Since there is not stupid question and I did use the search function, have a very simple question. I got my Calico bearing kit and the ARP (new gen) bolts based on what I have read on this thread. Unlike factory which is marked with a color code, these are purely gray (obvious) but I cannot make of which side is which (top or bottom). Do I need measurements in this case? Any other way (small marking etc.) that I am missing out on? Instructions didnt say squat. Secondly, anything else I need besides the bearing and bolts (engine oil pan etc.)? According to Turner, it was recommended that I get: 1 Genuine BMW Bearing Shell Yellow - 11217841609 1 Genuine BMW Guide-bearing Shell Yellow - 11217841613 I have not heard of these bearing shells and guide bearing shell. Are these required? Thank you in advance, this will be my first DIY on the bearings for the S65 and want to make sure I have all the ducks in a row. Malek, thanks for all the research. Regards, Lutfy |

|

Appreciate

0

|

| 03-30-2015, 09:42 AM | #359 | |

|

Lieutenant Colonel

427

Rep 1,947

Posts |

Quote:

|

|

|

Appreciate

0

|

| 03-30-2015, 09:52 AM | #360 | |

|

Lieutenant Colonel

427

Rep 1,947

Posts |

Quote:

If your bearings have 702/703 stamped on the back, then you will need to measure the bearing thickness to know which are the tops vs. bottoms. Tops will be about 0.0002 inch thicker than bottoms. Again, remove the material from the parting lines. You might want to hold off doing the DIY until I have a chance to measure and post the results of the ARP-625 rod bolts. If you look at the graphs above for the ARP-2000 rod bolts, they cause about 0.0006 inch bore distortion. I've since measured this on other rods and saw up to 0.0012 inch bore distortion on the ARP-2000's. Based on the clamp load numbers kawasaki posted, I think the ARP-625's will distort as well, but not as much as the ARP-2000's. I recommend you to give me a few days to measure and post the results before making an informed decision whether you should continue with the ARP-625's. BTW, Those are part numbers for main bearings. You don't need those for a rod bearing replacement. |

|

|

Appreciate

0

|

| 03-30-2015, 12:34 PM | #361 | |

|

Captain

252

Rep 633

Posts |

Quote:

Regards, Lutfy |

|

|

Appreciate

1

maicol76193.50 |

| 03-30-2015, 12:39 PM | #362 | |

|

BimmerPost Supporting Vendor

731

Rep 3,735

Posts  |

Quote:

The second engine in this thread failed due to the main bearings. There was no way around saving this engine even with a rod bearing replacement. In the other thread I've started with regards to rod bearing replacements, I will be posting up the results of another engine. That engine suffered from main bearing failure and the rod bearings looked rather terrible as well.

__________________

BMW PERFORMANCE SPECIALISTS. Race Engines. Suspension. F/I. Brakes. Race Preparation. Factory Service. Alignments.

OFFICIAL PARTNERS: KW. MOTON. Brembo. AP Racing. BBS Motorsport. iND. HRE. Turner Motorsport. VAC. BMW Motorsport. Facebook | Instagram | Yelp! | Flikr Phone: 949-233-0448 | E-Mail: info@mrfengineering.com |

|

|

Appreciate

0

|

| 04-27-2015, 10:31 AM | #363 | |

|

First Lieutenant

36

Rep 368

Posts |

Quote:

__________________

|

|

|

Appreciate

0

|

| 04-27-2015, 02:30 PM | #364 |

|

Lieutenant Colonel

427

Rep 1,947

Posts |

|

|

Appreciate

0

|

| 06-30-2015, 11:37 AM | #365 | |

|

Private First Class

59

Rep 109

Posts |

Quote:

I assume you'll post up what you find on the 625's very soon though. |

|

|

Appreciate

0

|

| 10-21-2015, 09:51 AM | #366 |

|

Enlisted Member

9

Rep 47

Posts |

Proper Engine Break-In Procedure

Hey guys, sorry for the slight thread-jack here, but I figured that this was as relevant a thread as any to ask people's opinion(s) on the proper break-in procedure (either after bearing replacement and/or total engine failure/rebuild)? I'm not a stranger to engine rebuilds and have performed a few rebuilds/swaps over the years, but just wanted to hear thoughts on how we're doing it w/our BMW engines. Specifically interested to hear thoughts on:

-break-in oil type -break-in duration & when to change break-in oil -oil brand/type after break-in (this has been pretty much beaten to death, & is still controversial & a bit subjective, but would entertain further comments) TIA!!! EDIT: Sorry, forgot! Just wanted to thank Malek & everyone else real quick for all of their hard work, and for the knowledge that they have willingly and openly shared on this forum! |

|

Appreciate

0

|

| 10-24-2015, 11:24 AM | #367 | |

|

First Lieutenant

194

Rep 362

Posts |

Quote:

No special oil during break in period, use 10W-60 or whatever grade you feel comfortable with.

__________________

|

|

|

Appreciate

0

|

| 10-28-2015, 09:29 AM | #368 | |

|

Enlisted Member

9

Rep 47

Posts |

Quote:

|

|

|

Appreciate

0

|

| 12-09-2015, 03:36 PM | #369 |

|

First Lieutenant

196

Rep 386

Posts |

Not sure if I missed it or not (this is a great, long informational thread), but did Malek hone the big ends of the rods with the new bolts during the original bearing swap of the engine this thread was started about?

Just curious because I just spun a bearing on rod #2 (2008 80k manual never tracked) and a low mileage used engine is on my short list. That being said, before I drop the (n)used engine in I was planning on proactively doing the VAC/ARP treatment. Thanks! |

|

Appreciate

0

|

| 01-23-2016, 05:53 PM | #370 |

|

Know's a guy that know's a guy...

5637

Rep 1,905

Posts |

Bump - any updates?

|

|

Appreciate

0

|

| 03-03-2016, 03:47 AM | #371 | |

|

Private First Class

59

Rep 109

Posts |

Quote:

If you really believe that bearing clearance is the issue with this motor, you should be removing the crankshaft, having the journals polished down, and installing the loosest main and rod bearings you can find. Why is the rod bearing clearance the only focus here? |

|

|

Appreciate

0

|

| 03-03-2016, 07:05 AM | #372 | ||

|

Grease Monkey

294

Rep 2,646

Posts

Drives: 2011 E90 M3,1994 Euro E36 M3/4

Join Date: Apr 2006

Location: Fort McMurray, Alberta, Canada

|

Quote:

It is known that the main clearance is also tight, but they don't seem to fail since there have only been 3 cases that I can recall of main bearing failure being posted on here. The rod bearings are done because there have been lots of cases of rod bearing failures and they can be done without pulling the engine. In the event of someone doing a full engine rebuild, it is recommended by all of us rod bearing c/o proponents to have the rod side clearance set and crank journals polished to size. The fact of the matter is that most people are not going to be doing full rebuilds so they address the method of failure that is most prominent by doing the rod bearings. |

||

|

Appreciate

0

|

| 04-15-2016, 03:42 PM | #374 | |

|

BimmerPost Supporting Vendor

731

Rep 3,735

Posts  |

Quote:

I have opened up many cars now that had bearings replaced, were raced/tracked/driven on average 10,000+ miles and came back in for check ups. The new bearings just like the one posted in this thread exhibit no wear. |

|

|

Appreciate

2

M3_Legend352.00 |

Post Reply |

| Bookmarks |

|

|