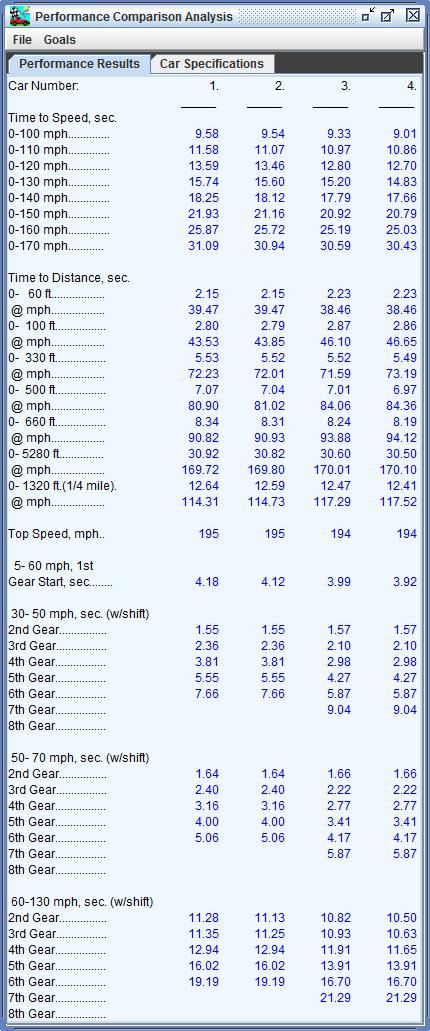

Here is CARTEST data that shows the change from 8300 to 8600 RPM redline makes virtually no difference. 0-1/4 mile and even 0-170 made virtually no difference. Strangely, 60-130 does seem to make more difference than 0-170. Maybe some of the smarter people can explain that.

All of the results below come from the same car dyno input into cartest. It's a 400+ whp FBO M3 that is one of the strongest dyno's to date. Dyno data was input into CarTest and results are compared to see if extra 300 RPMs makes any difference.

The columns below are as follows

1. FBO M3 6MT @ 8300

2. FBO M3 6MT @ 8600

3. FBO M3 DCT @ 8300

4. FBO M3 DCT @ 8600

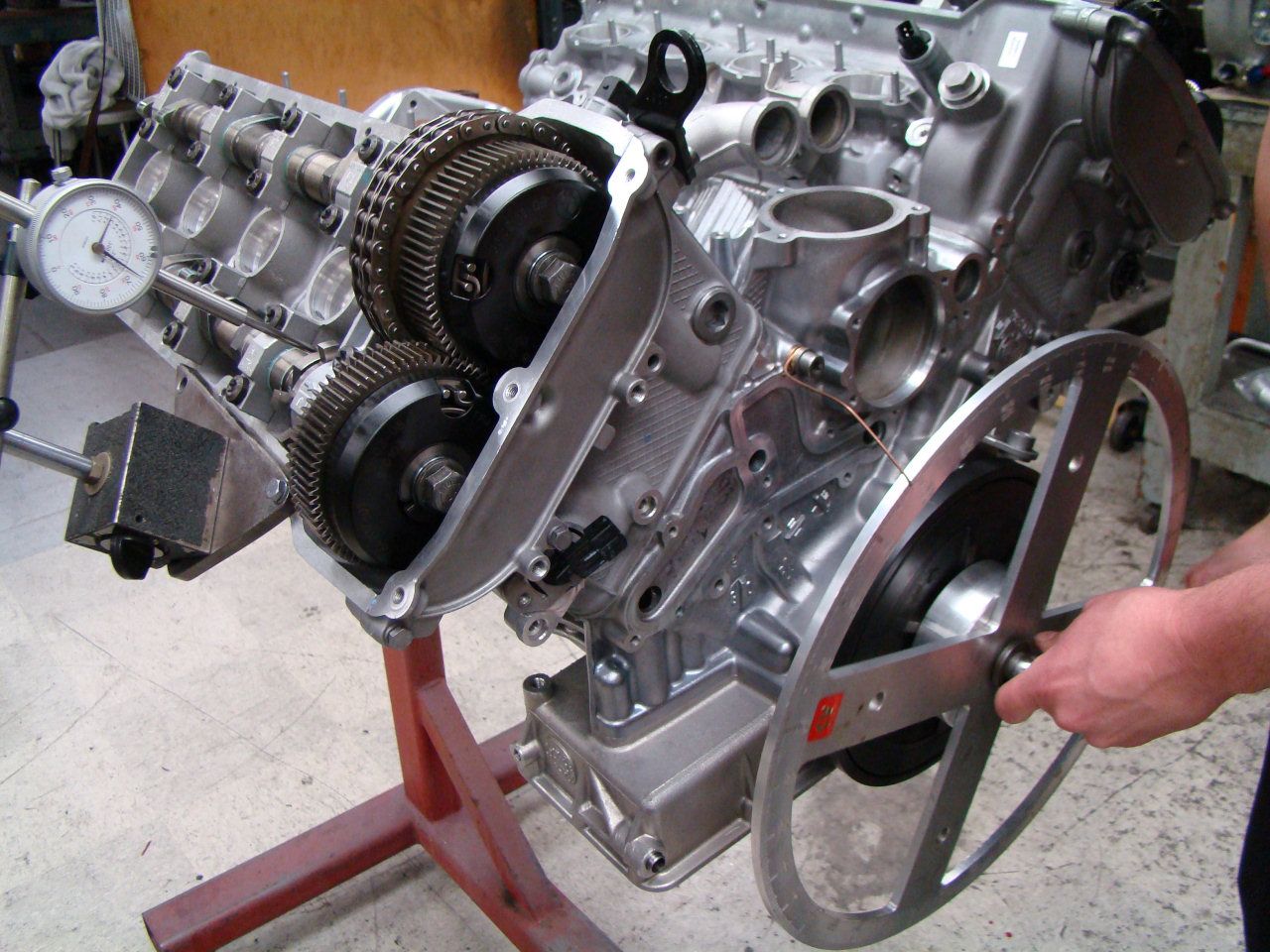

You can see from this picture that this is a very serious S65 build...possibly the most serious build to date. This build measured every spec and every clearance of the S65 engine. For valve springs, they measured seat pressure at various lifts and how much lift the spring can take before coil bind. It was the shop's opinion that the factory valve springs didn't have enough seat pressure beyond factory specs (8400 RPMs and 11.5mm lift). They didn't like the idea of increased redlines or higher lift cams with these factory springs. Maybe others might disagree and maybe the shop is too conservative, but that's what they said after measuring the stock springs.

They decided to change to aftermarket valve springs on this build. The aftermarket springs have 80% more seat pressure and can take 1mm more lift than factory valve springs.