Quote:

Originally Posted by Bolas997

Its not an ADV.1 fatigue issue, it has to do with an inner barrel part used for that particular set. the part is derived from the same manufacturer HRE uses for their wheels. I think ADV.1 has handled the situation perfectly.... i just dont know why people are trying to bash them for this?

|

We’ve been alerted that HRE is being dragged into this thread. While we don’t want to be anywhere near this, unfortunately our name is getting tossed around so we are forced to clarify some of the statements being made.

- HRE Banned from Racing?: Regarding the ban from racing in the 2000’s, this is FALSE. Unfortunately this was a rumor created by the boyfriend of an Audi customer that was unhappy with us. We took this very seriously and contacted all of the racing sanctioning bodies and the Viper Racing League (which is the event the supposed failures occurred) and it was all shown to be false. Unfortunately HRE at that time had a “hands off” policy on the forums and this rumor spread like wildfire; leaving us even today having to defend ourselves. We were also way too soft with our use of legal protection. Today we would not let a rumor like this spread without serious repercussions to the perpetrator, particularly when the intention was clearly to simply hurt our reputation with false information.

- Rim Suppliers: HRE purchases our rims from 2 suppliers in the U.S. We have had rim failures on the inner flange (not the same location as this failure) primarily on older rims manufactured and sold years ago. This can be caused by work-hardening during manufacture but also due to other factors, including some user issues like running with low tire pressure. While this issue is rare today, we worked with our suppliers to have them roll the inner rim flange on all their parts to ensure this never happens. These rims are being incorporated into our stock now as they make the transition. The rest of the industry will get this improvement as well of course. We keep inventory on rim parts needed for our wheels at our 60,000 sq ft facility.

- HRE wheel failures?: HRE has experienced wheel failures, particularly on older models from years ago. HRE has been in business for a long time and the strength and quality of our wheels is substantially different today then say in the ‘90s. Even today we challenge ourselves with our racing efforts and while we have and will continue to win championships, we recognize the possibility of having a potential failure in the future given the nature of pushing the limit in professional motorsport. In fact, a well designed motorsport wheel will eventually have its fatigue life run out of it and fail if it is not retired after its useful life. However, we do NOT expect to have wheel failures on the street. We have a LIFETIME STRUCTURAL WARRANTY for a reason. Our wheels are meant to be lightweight but they should still last the life of your vehicle so if it has our name on it we will take responsibility for it.

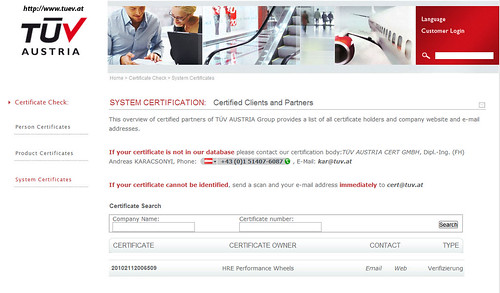

- Quality: Please do not equate the use of similar suppliers with similar quality. HRE does our design/engineering/CNC machining/finish/assembly here in Vista (San Diego, CA) at our OWN facility with our OWN quality management process that is TUV certified. We’re not just talking about wheels being certified. Our QUALITY MANGEMENT SYSTEM is TUV certified.

- Engineering: Our president has a B.S. from Harvey Mudd College in Engineering and an M.S from UCLA in Mechanical Engineering and came to us in 1999 after 8 years of working at Northrop Grumman’s B-2 Division doing structural analysis on aircraft. The fact that HRE has a mechanical engineer in such a lead position should make it clear we’re not just a “draw and cut” company and how proper engineering is viewed here. As for FEA we know it is way too easy to get a very “accurate INCORRECT answer”. If you have no idea what you’re doing, you’re going to end up with false confidence leading to problems. Junk in. Junk out.

- Does this failure affect HRE?: HRE has never experienced and does not expect to experience a failure of the nature exhibited here. After concerns were raised we had discussions with our suppliers and our own engineering team here and feel that this is not an issue that will affect HRE or requires any changes to our quality management system, wheel designs, or suppliers. It is easy to look at a cracked rim and immediately assume the failure is due to the rim, but the center design and quality of manufacture along with the assembly design and quality of the process are key to ensuring parts do not exceed their design limits.

If you have any more questions, feel free to contact me directly at

lonm@hrewheels.com or call our main office at 760-598-1960.

Feel free to verify our TUV certification here,

http://www.tuev.at/start/browse/Webs...rter%20Partner