Quote:

Originally Posted by regular guy

Part-1: Rod bolt clamping pressure:

M3post reader, kawasaki00 measured the OEM rod bolt clamping pressure, along with the clamping pressure of two different types of Carrillo rod bolts. As he discovered, the OEM rod bolts offer far more clamping pressure vs. Carrillo rod bolts, and it's believed the clamping pressure (or lack thereof) may cause the rod big end bore distortion and lead to increased bearing clearance at 90-degrees. Increased bearing clearance is a good thing, but bore distortion is not. I'm pretty sure that increased clearance at the cost of bore distortion is not advised. However, I'll let kawasaki00 and the other engine experts comment on that.

Here's the rod bolt clamping force data generated by kawasaki00:

| | | At Torque | Over Torque | | Bolt Type | 53 in/lb | 177 in/lb | 130 degrees | +20 degrees | | OEM Rod Bolt #1 | 1169 | 3075 | 10933 | 11570 | | OEM Rod Bolt #2 | 1101 | 2998 | 10855 | 11323 | | | | | | | Bolt Type | | 22 ft/lbs | 50 degrees | +20 degrees | | Carrillo WMC #1 | | 4200 | 8160 | 10211 | | Carrillo WMC #2 | | 4189 | 8110 | 10301 | | Carrillo SPS | | 3270 | 7870 | |

Notes:

Carrillo WMC bolts @ 50 degrees, 0.006 inch stretch

Carrillo SPS bolts @ 54 degrees, 0.0065 inch stretch

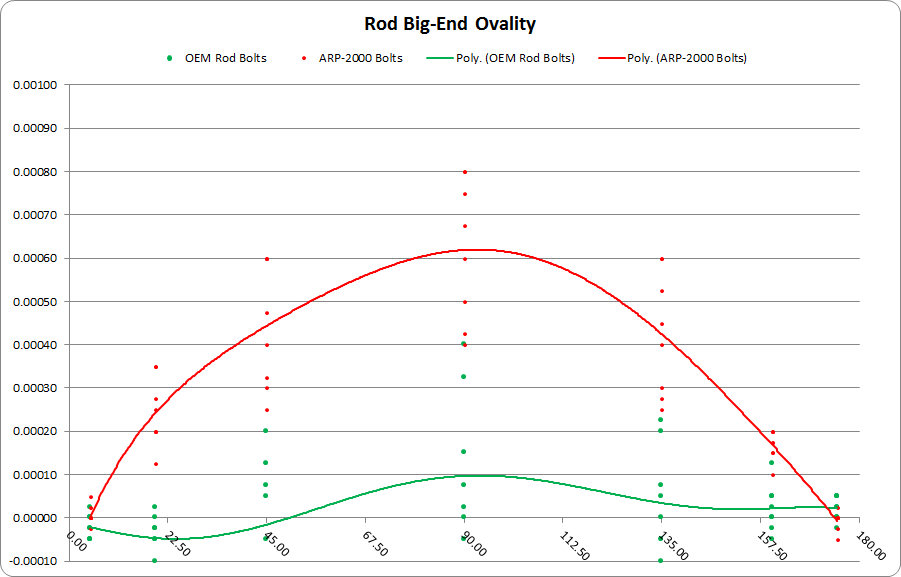

Part-2: Rod big-end ovality with different rod bolts:

With the rod bolt clamping data above, the next test will see which rod bolt creates the roundest circle. This will test for the "ovality" of the rod big end bore by checking the measurements at seven different points around the circle. Although the ARP-2000 and ARP-625 rod bolts were not tested above, I believe the two Carrillo rod bolts are of similar quality and specifications. (kawasaki00 can comment on that.)

For the most part, the OEM rod bolts create a near perfectly-round circle. Four of the eight rods I tested were 1/10000th of an inch or less out of round. That's probably what you would expect since these rods were honed (the process of making the circle round) with OEM rod bolts.

The ARP-2000 rod bolts did not create a perfectly round circle. The ARP-2000 rod bolts, with less clamping pressure produced bore distortion at 90-degrees. The bore distorts larger towards 90-degrees, and this would explain Malek's and Van Dyne's measurement of increased clearance when using the aftermarket ARP bolts. But is this enough to matter? Kawasaki00 told me privately, yes, this is a significant amount of ovality, and he would not use these bolts unless he was also able to rehone the connecting rod big ends to make them round again.

The data:

OEM Rod Bolt Measurements:

Torque Specifications: 20 Nm + 130 degrees

| Degrees | OEM Rod Bolts | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | | Ambient Temperature | 76.4 | 76.3 | 76.2 | 76.1 | 76.0 | 76.1 | 76.1 | 76.0 | | 5.00 | | 2.20490 | 2.20495 | 2.20520 | 2.20500 | 2.20510 | 2.20520 | 2.20515 | 2.20510 | | 19.75 | | 2.20490 | 2.20500 | 2.20510 | 2.20500 | 2.20500 | 2.20520 | 2.20510 | 2.20510 | | 45.00 | | 2.20500 | 2.20510 | 2.20515 | 2.20520 | 2.20500 | 2.20500 | 2.20500 | 2.20520 | | 90.00 | | 2.20510 | 2.20530 | 2.20515 | 2.20540 | 2.20515 | 2.20510 | 2.20515 | 2.20520 | | 135.00 | | 2.20500 | 2.20520 | 2.20520 | 2.20520 | 2.20510 | 2.20515 | 2.20500 | 2.20520 | | 160.25 | | 2.20500 | 2.20510 | 2.20520 | 2.20500 | 2.20520 | 2.20520 | 2.20510 | 2.20515 | | 175.00 | | 2.20500 | 2.20500 | 2.20520 | 2.20500 | 2.20520 | 2.20530 | 2.20510 | 2.20515 |

Ovality:

| Degrees | OEM Rod Bolts | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | | Ambient Temperature | 76.4 | 76.3 | 76.2 | 76.1 | 76.0 | 76.1 | 76.1 | 76.0 | | 5.00 | | -0.00005 | -0.00002 | 0.00000 | 0.00000 | -0.00005 | -0.00005 | 0.00003 | -0.00002 | | 19.75 | | -0.00005 | 0.00002 | -0.00010 | 0.00000 | -0.00015 | -0.00005 | -0.00002 | -0.00002 | | 45.00 | | 0.00005 | 0.00012 | -0.00005 | 0.00020 | -0.00015 | -0.00025 | -0.00012 | 0.00008 | | 90.00 | | 0.00015 | 0.00032 | -0.00005 | 0.00040 | 0.00000 | -0.00015 | 0.00003 | 0.00008 | | 135.00 | | 0.00005 | 0.00022 | 0.00000 | 0.00020 | -0.00005 | -0.00010 | -0.00012 | 0.00008 | | 160.25 | | 0.00005 | 0.00012 | 0.00000 | 0.00000 | 0.00005 | -0.00005 | -0.00002 | 0.00003 | | 175.00 | | 0.00005 | 0.00002 | 0.00000 | 0.00000 | 0.00005 | 0.00005 | -0.00002 | 0.00003 |

ARP-2000 Rod Bolt Measurements:

Torque Specifications: 45 Ft-Lbs

| Degrees | OEM Rod Bolts | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | | Ambient Temperature | 75.4 | 75.2 | 75.5 | 75.8 | 75.6 | 75.2 | 75.7 | 75.3 | | 5.00 | | 2.20500 | 2.20500 | 2.20520 | 2.20500 | 2.20520 | 2.20515 | 2.20520 | 2.20515 | | 19.75 | | 2.20520 | 2.20535 | 2.20540 | 2.20535 | 2.20540 | 2.20530 | 2.20540 | 2.20540 | | 45.00 | | 2.20560 | 2.20560 | 2.20560 | 2.20560 | 2.20550 | 2.20550 | 2.20540 | 2.20560 | | 90.00 | | 2.20575 | 2.20580 | 2.20580 | 2.20580 | 2.20560 | 2.20560 | 2.20565 | 2.20580 | | 135.00 | | 2.20560 | 2.20540 | 2.20565 | 2.20560 | 2.20550 | 2.20545 | 2.20540 | 2.20565 | | 160.25 | | 2.20520 | 2.20520 | 2.20530 | 2.20520 | 2.20535 | 2.20535 | 2.20530 | 2.20530 | | 175.00 | | 2.20500 | 2.20500 | 2.20520 | 2.20500 | 2.20520 | 2.20520 | 2.20510 | 2.20510 |

Ovality:

| Degrees | OEM Rod Bolts | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | | Ambient Temperature | 75.4 | 75.2 | 75.5 | 75.8 | 75.6 | 75.2 | 75.7 | 75.3 | | 5.00 | | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | -0.00002 | 0.00005 | 0.00003 | | 19.75 | | 0.00020 | 0.00035 | 0.00020 | 0.00035 | 0.00020 | 0.00012 | 0.00025 | 0.00028 | | 45.00 | | 0.00060 | 0.00060 | 0.00040 | 0.00060 | 0.00030 | 0.00032 | 0.00025 | 0.00048 | | 90.00 | | 0.00075 | 0.00080 | 0.00060 | 0.00080 | 0.00040 | 0.00042 | 0.00050 | 0.00068 | | 135.00 | | 0.00060 | 0.00040 | 0.00045 | 0.00060 | 0.00030 | 0.00027 | 0.00025 | 0.00053 | | 160.25 | | 0.00020 | 0.00020 | 0.00010 | 0.00020 | 0.00015 | 0.00018 | 0.00015 | 0.00018 | | 175.00 | | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00002 | -0.00005 | -0.00002 |

Graph(s):

Next Steps:

Next Steps:

Next week, ARP-625 bolts will arrive. I will repeat this measuring process with the ARP-625 bolts and post the results when they are available.

Thanks to Malek for loaning me the ARP-2000 rod bolts. Before returning them, I plan to measure bearing clearance.

|

Thanks for the measurement and gathering all the info.

I wonder what this implies for those of us that used the ARP2000 rod bolts.

Is that .0005 differential with the oem bolt that significant? If I recall, the bore is not exactly round once the bearing is in place anyway, right? Should we open up the engine and change the rod bolt asap? Will wait to see the result with the 625+ one. Thank you once again.