|

03-26-2012, 05:20 PM

|

#363

|

Lieutenant Colonel

Drives: N/A

Join Date: Feb 2011

Location: Miami, FL

|

ADV.1 Testing Procedures and documentation

Due to the recent rumors circulating the internet we felt it was necessary to explain our testing, engineering, and warranty procedures for those interested.

Testing Procedures:

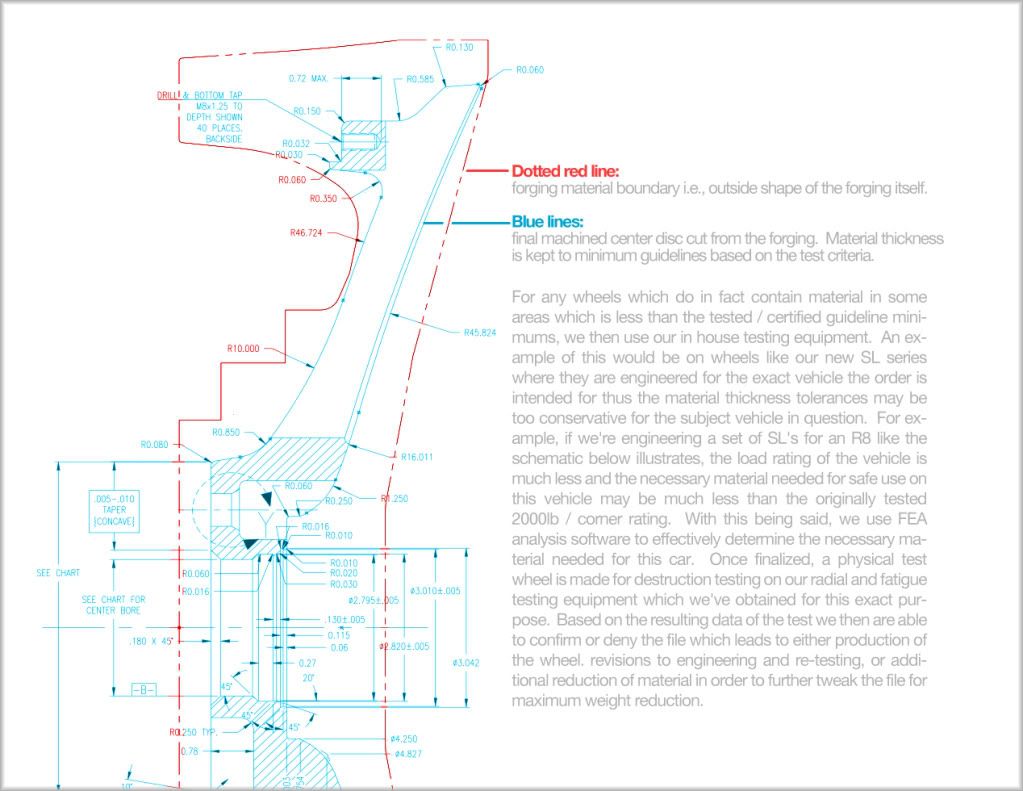

All of our forgings are initially engineered around a certain range of vehicle fitments / load ratings. Normally we design the forging die itself around a 2000lb. per corner load rating umbrella. This means that so long as all wheels using this forging are engineered around the tested / certified material thickness minimums based on the test certification, no further testing is required unless an order violates these guidelines for any reason. To give you an example of this, see diagram below.

For any wheels which do in fact contain material in some areas which is less than the tested / certified guideline minimums, we then use our in house xxx testing equipment. An example of this would be on wheels like our new SL series where they are engineered for the exact vehicle the order is intended for thus the material thickness tolerances may be too conservative for the subject vehicle in question. For example, if we're engineering a set of SL's for an R8 like the schematic below illustrates, the load rating of the vehicle is much less and the necessary material needed for safe use on this vehicle may be much less than the originally tested 2000lb / corner rating. With this being said, we use FEA analysis software to effectively determine the necessary material needed for this car. Once finalized, a physical test wheel is made for destruction testing on our radial and fatigue testing equipment which we've obtained for this exact purpose. Based on the resulting data of the test we then are able to confirm or deny the file which leads to either production of the wheel. revisions to engineering and re-testing, or additional reduction of material in order to further tweak the file for maximum weight reduction.

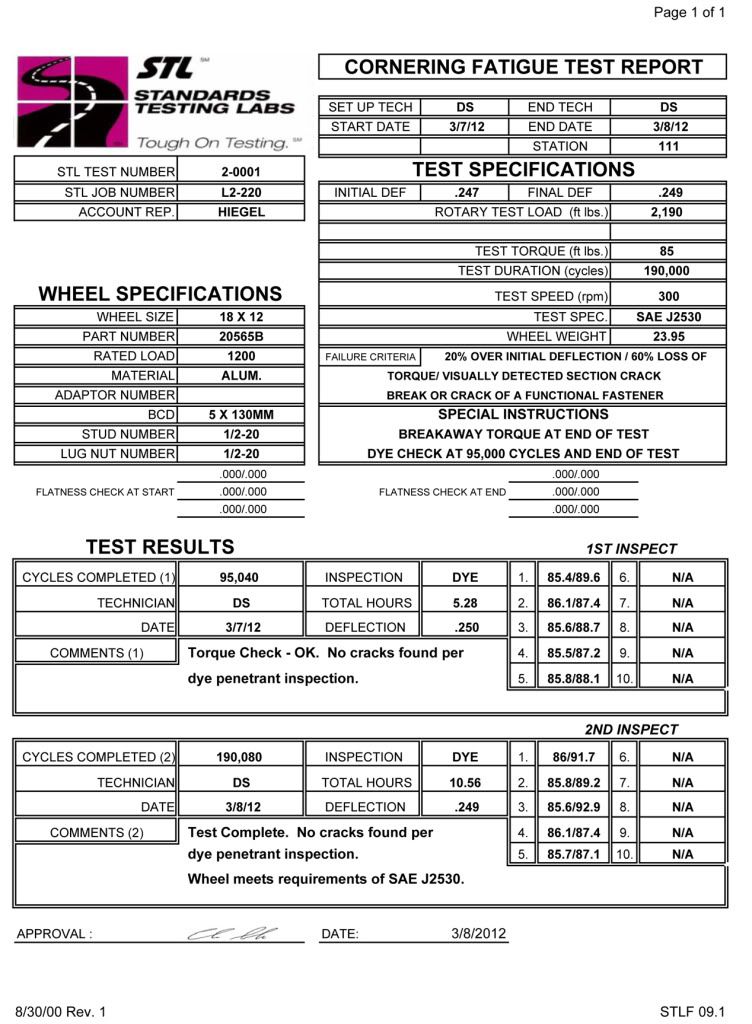

Testing procedures of the initial forging / umbrella certification is done by a company called STL or Standard Testing Labs. This is a US based, independent testing facility which provides multiple types of testing procedures. For each individual test subject a certification outlining the results and details is provided, see examples below which we have on file for all ADV.1 Forgings used.

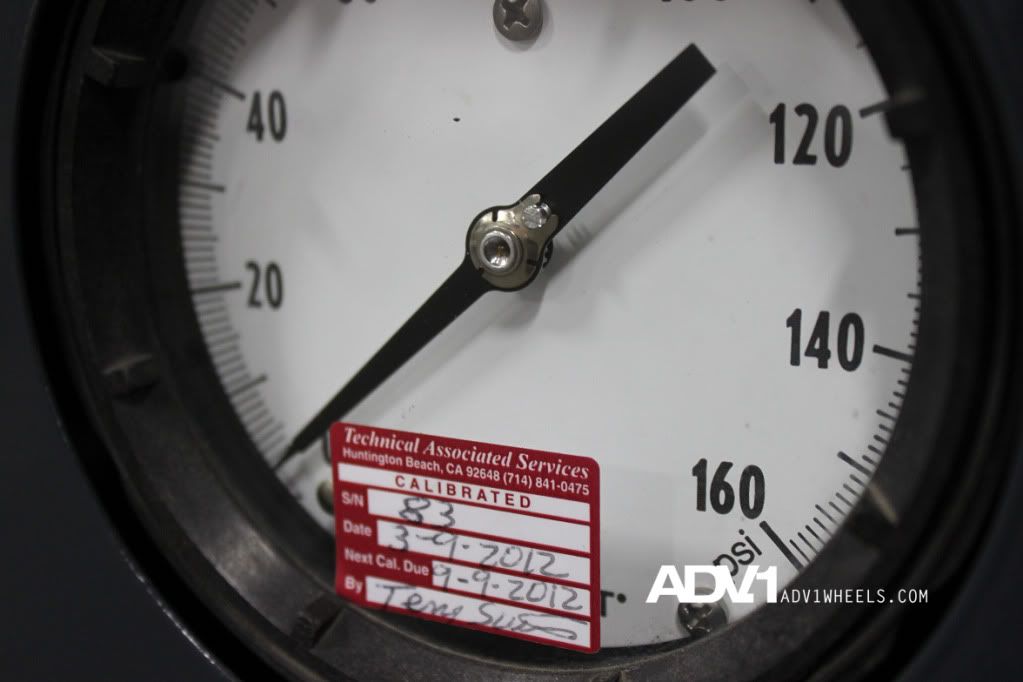

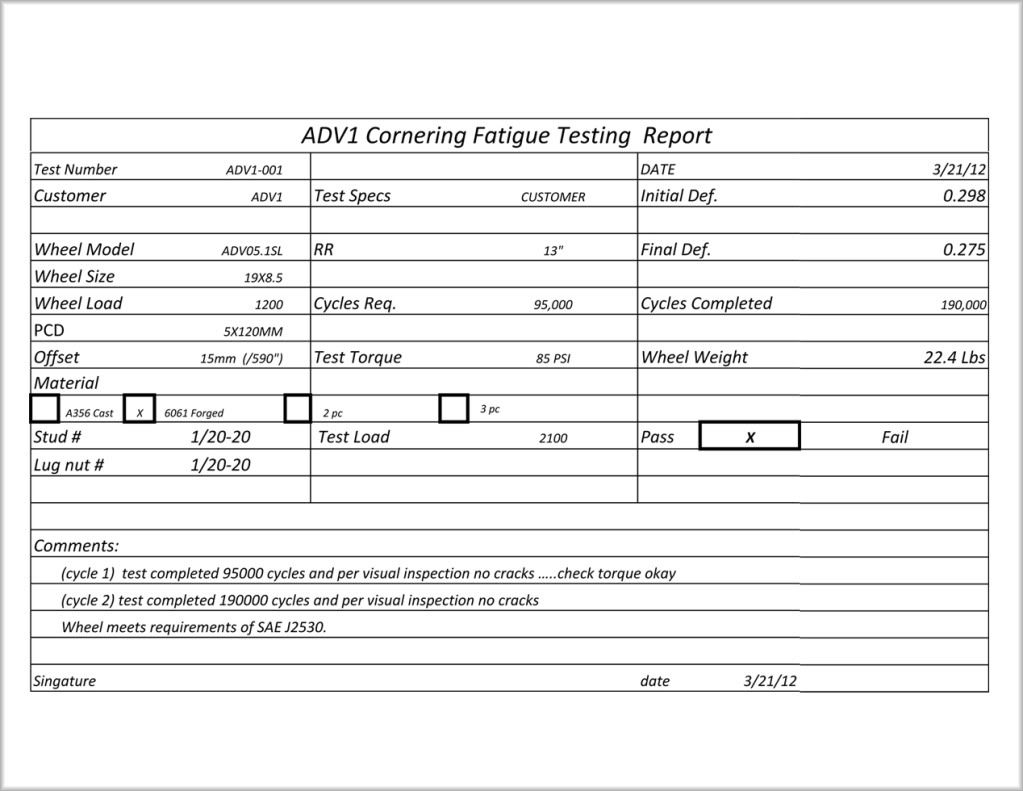

Our in house radial cornering / fatigue testing equipment also provides documentation on each subject tested, an example of such is shown below:

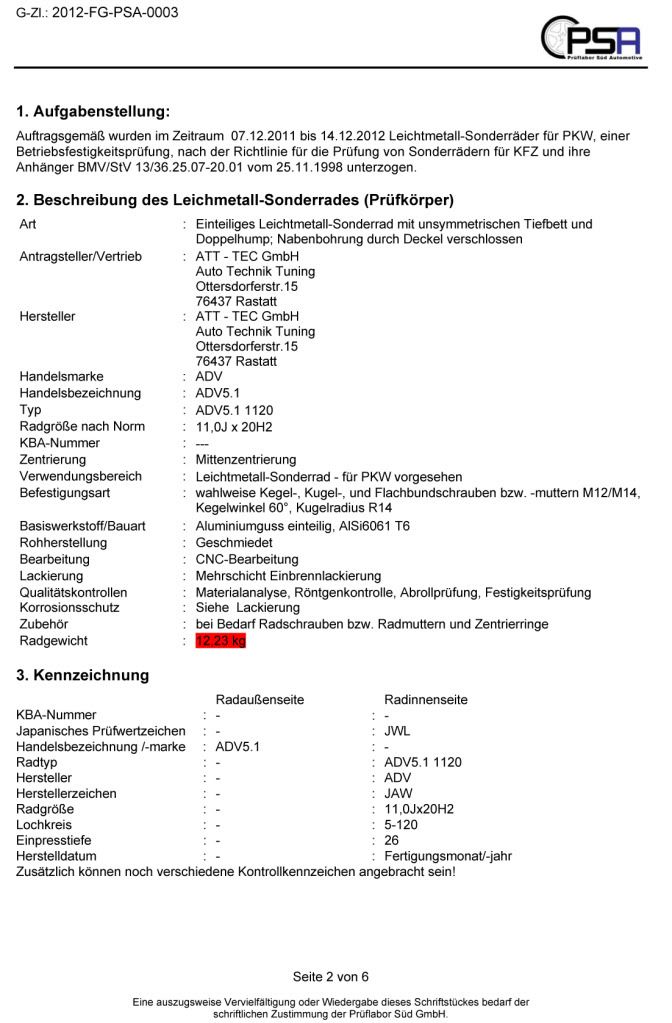

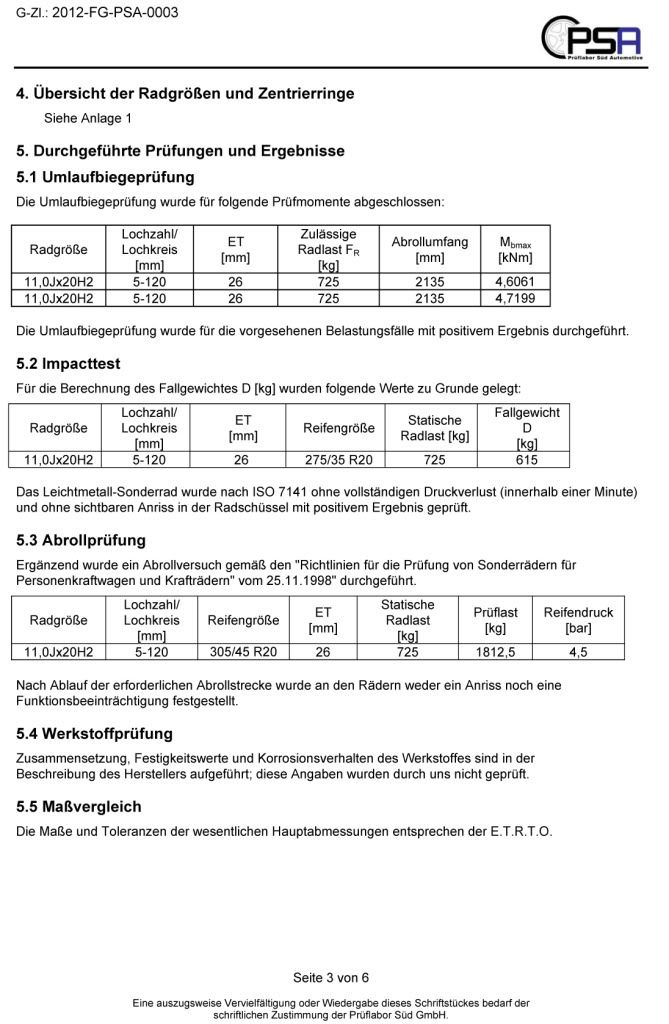

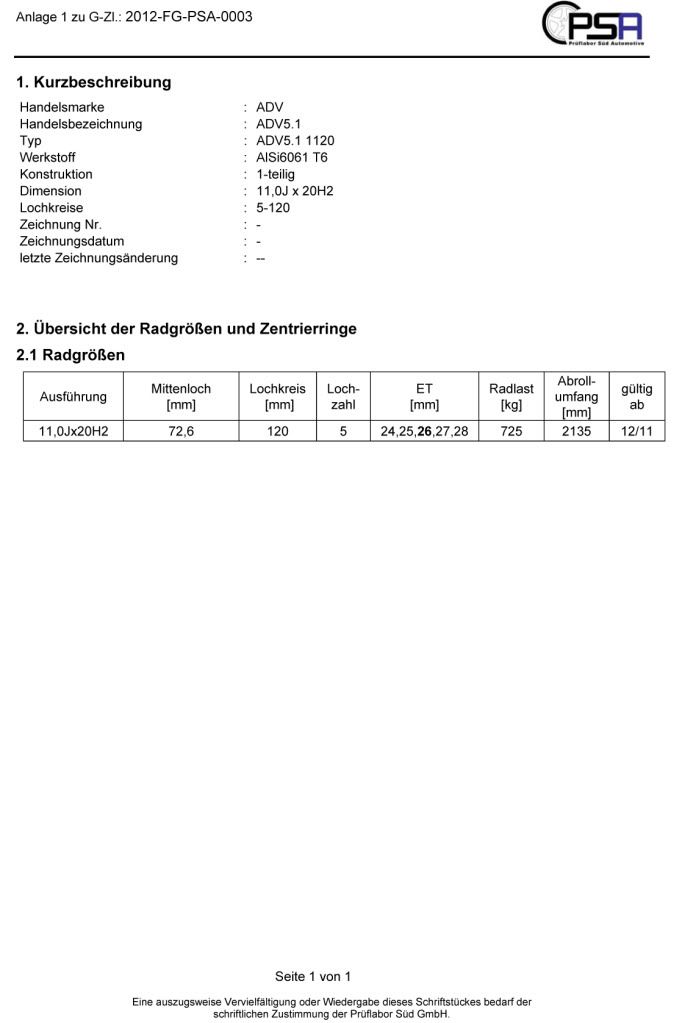

In regards to TUV Testing, as many know is something we've been working diligently towards with our German Partners, ATT-Tec in Berlin, is a long process and despite what many believe is actually a never ending requirement needed for every single size, offset, application, PCD, etc. The process is very expensive and time consuming however is the only way to provide customers in Germany with aftermarket products of any type. Below is a detailed explanation written recently by Jordan Swerdloff on this subject:

"TUV requires individual testing and certification documents for every single wheel style, in each size, for each application so there's still a long road ahead of us in order to be able to offer all styles to a wide range of vehicles. So far we officially have our ADV5.1 monoblock approved in 20x8.5+18 / 20x11+20 for BMW e92 M3. Each additional certification will only require roughly a week for testing / approval now that the TUV recognizes the company as an approved manufacturer which will soon be added to their database once the paperwork is complete, the majority of the documentation and testing is not needed for each additional certification. Current plans for the remainder of 2012 will include 18 more certifications, 3 styles in both 1 piece and 3 piece track spec configurations, offered to 3 different vehicle platforms.

Although there is still a long way to go, this is a huge step in the process of opening the door to Germany. Currently the selection of wheels able to be sold is very limited and the only option enthusiasts have is to either choose from the limited selection of approved brands, mostly cast wheels or to risk fines and even the loss of their vehicles by driving without TUV certified products on their car. Now, through the efforts of our Exclusive German Distributors ATT-Tec, the German market will finally be able to enjoy our wheels without having to worry about the consequences of driving without approved aftermarket components on their vehicles."

ADV.1 Materials / Suppliers

3 Piece center disc forgings:

Material: 6061 T6 Heat Treated Forged Aluminum

Suppliers:

ASA

Centerline

1 Piece monoblock forgings:

Material: 6061 T6 Heat Treated Forged Aluminum

Suppliers:

ASA

3 Piece rim halves / excluding 21/22 inch Standard reverse parts (step lip):

Material: 5051 Spun Forged Aluminum / 6061 T6 Heat Treated Forged Aluminum

Suppliers:

ARS

Triangle

3 Piece 21/22 inch Standard reverse parts (step lip) rim halves:

Material: 6061 T6 Heat Treated Forged Aluminum

Suppliers:

Triangle

Machining:

Performed: In house / ADV.1 Dedicated portion of MHT Machining Production Facility

Engineering / Programming:

Performed: In house / ADV.1 Staff

|

|

|

|